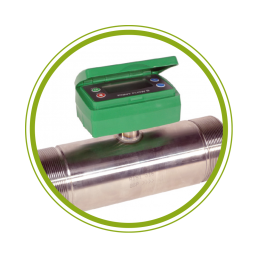

The Polmac flowmeters

The Polmac flowmeters are constructed paying the utmost attention to the quality of the materials used.

The outer body is made of AISI 316 stainless steel and houses support components in PVDF and ceramic, and a steel turbine coated with a special PTFE treatment.

The entire range of flowmeters has been subjected to global and specific migration testing in compliance with the regulations in force for conformity of food contact products, more precisely, food-grade liquids such as milk, wine, beer, vinegar, oil and water.

WINE

WATER

VINEGAR

OIL

BEER

MILK

Polmac flowmeters regulations

Passing these tests allows us to provide the end customer with a declaration of conformity.

This declaration of conformity certifies that the Polmac flowmeters are in compliance with the following regulations:

EC LEGISLATION:

• Regulation 1935/2004/EC

• Regulation 10/2011/EC and subsequent amendments

ITALIAN LEGISLATION:

• Ministerial Decree of 21/03/1973 and subsequent amendments and integrations

• Legislative Decree of 4/04/1985, Annex 1, and subsequent amendments and integrations

• Legislative Decree No. 29 of 10 February 2017

Technical features:

Some technical data of the Polmac flowmeters:

– Precision class: ±1%

– Maximum operating pressure: 50 bar

– Measuring range: 7 to1500 l/min (range covered by the sizes between 3/4” and 3”)

– Operating temperature: -10 to +70°C

Furthermore, Polmac manufactures sensors to be coupled to its flowmeters with various output signals (sinusoidal wave, square wave or Hall effect) to satisfy the various system interfacing requirements.

Polmac also manufactures 9V battery-powered or 12V cable-powered displays to view total and partial flows.

The 9V displays can be installed directly on the flowmeter as they are equipped with a sensor.

The 12V displays require a sensor and can be positioned at a distance.

Some 12V models can provide an output signal when a set total is reached, to control a motor, solenoid valve or acoustic signaller.